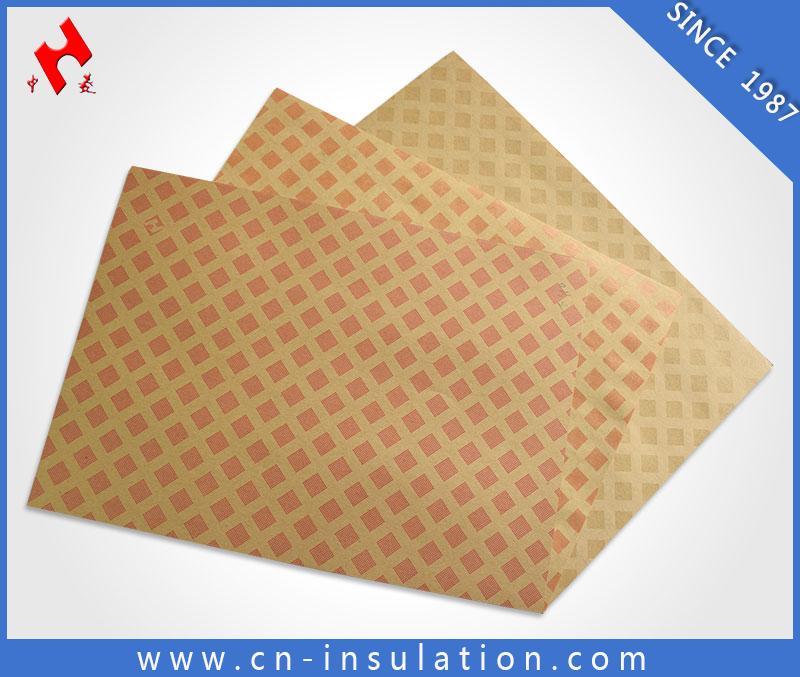

Diamond Dotted Insulation Paper

Key words:

Oil-Immersed Transformer Insulating Materials | Mutual Inductor Insulation Materials

Classification:

Product Description

Diamond dotted insulation paper (DDP) is made by coating a special modified epoxy resin on the high-performance insulating paper. It is widely applied in the interlayer insulation and turn insulation of oil-immersed power transformers. The coating layer begins to melt at a certain temperature during the drying process of coil when in use, resulting in a sticky effect. As the temperature rises, the coating layer begins to solidify again, securely bonding adjacent layers of the winding into a fixed unit. The adhesive strength of the epoxy resin is sufficient to prevent the displacement of winding layers during short circuits, thereby ensuring the long-term mechanical and electrical performance of the insulation structure.

As the resin coating of the DDP is in the form of dots, it ensures the infiltration of oil and the exhaustion of gases in the insulating material, effectively preventing corona discharge and partial discharge, thus ensuring the safety and reliability of the insulating structure.

Product Curing Conditions:

Initially maintained at 90℃ ± 5℃ for 3 hours, followed by a further 6 hours at 125℃ ± 5℃ to ensure complete curing.

Storage:

It shall be stored in a dry and clean room with a temperature not exceeding 25℃ and must be kept away from fire sources, heaters, and direct sunlight. The shelf life is one year, and it can still be used if it passes the inspection after exceeding the storage period.

|

Serial Number |

Sex Can |

Unit |

To Ask |

|||||

|

1 |

Substrate thickness and tolerance |

mm |

0.08±0.005 |

0.13±0.007 |

0.18±0.010 |

0.20±0.010 |

0.25±0.010 |

|

|

2 |

substrate tightness |

g/cm³ |

0.85-1.10 |

|||||

|

3 |

Single-sided adhesive thickness |

um |

6-12 |

|||||

|

4 |

Moisture |

% |

4.0-8.0 |

|||||

|

5 |

Ash |

% |

≤1.0 |

|||||

|

6 |

conductivity of water extract |

ms/m |

≤10 |

|||||

|

7 |

PH value of water extract |

- |

6.5-8.5 |

|||||

|

8 |

oil absorption |

% |

≥20 |

|||||

|

9 |

bond strength |

Normal |

kpa |

≥ 650 |

||||

|

100 ℃ ± 2 ℃ |

||||||||

|

10 |

Contamination of transformer oil |

- |

No pollution (tan δ<0.001) |

|||||

|

11 |

Tensile strength |

Vertical |

N/10mm wide |

≥60 |

≥ 110 |

≥160 |

≥180 |

≥ 230 |

|

Transverse |

||||||||

|

12 |

Tear strength |

Vertical |

mN |

≥450 |

≥ 900 |

≥ 1350 |

≥ 1500 |

≥ 2000 |

|

Transverse |

≥500 |

≥1000 |

≥ 1500 |

≥ 1700 |

≥ 2300 |

|||

|

13 |

breakdown voltage |

in the air |

kv |

≥ 0.88 |

≥ 1.37 |

≥ 2.00 |

≥ 2.10 |

≥ 225 |

|

In oil |

≥ 4.40 |

≥ 7.00 |

≥ 9.00 |

≥ 9.80 |

≥ 11.50 |

|||

Zhongling insulation material

Related Products

Product inquiry