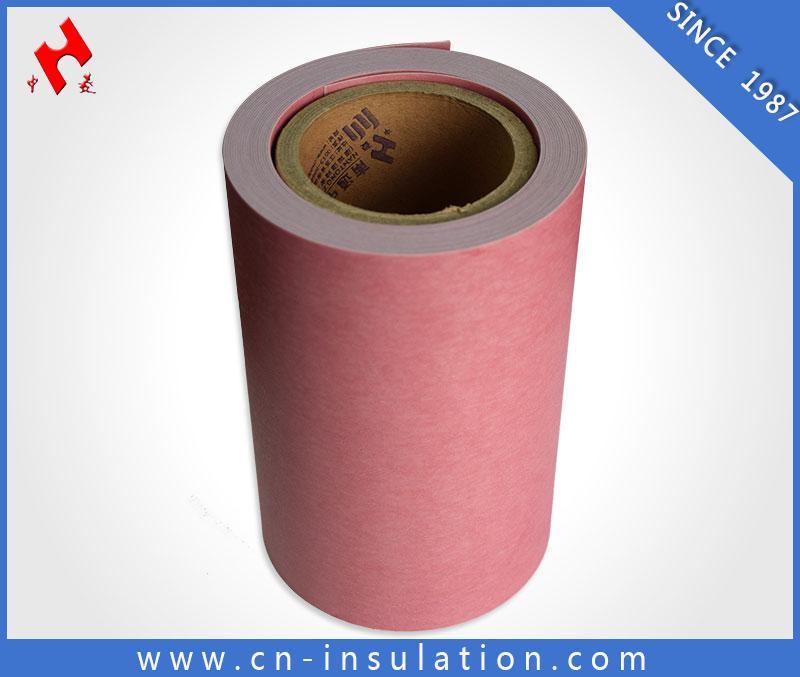

Electrical Composite Coaming Board

Key words:

Oil-Immersed Transformer Insulating Materials | Mutual Inductor Insulation Materials

Classification:

Product Description

The composite coaming board is fabricated through a multilayered composite process consisting of polyester film coated with a specialized heat-resistant adhesive and polyester fiber non-woven fabric. It is further treated with a special resin surface coating and is primarily utilized as a sleeve between the high and low voltage coils in dry-type transformers.

Note: The recommended widths for this product are 780 mm, 880 mm, 1,040 mm, and 1,240 mm, and they can be custom-made based on customer requirements.

Storage: Store the product upright in a dry, well-ventilated, and clean room-temperature environment. It should not be placed near fires, heat sources, or in direct sunlight. The shelf life is 12 months, and it can still be used if it passes the inspection after exceeding the storage period.

|

Serial Number |

Performance |

Unit |

Requirements |

|||

|

1 |

Thickness and Tolerance |

mm |

0.5±0.045 |

0.83±0.066 |

0.9±0.09 |

|

|

2 |

Quantification and Tolerance |

G/square meter |

622±68 |

1085±87 |

1120±112 |

|

|

3 |

film thickness |

Μm |

350 |

350 |

350 |

|

|

4 |

Number of film layers |

V |

1 |

2 |

2 |

|

|

5 |

Tensile strength |

Vertical |

N/10mm |

≥350 |

≥600 |

≥600 |

|

Transverse |

≥350 |

≥600 |

≥600 |

|||

|

6 |

Elongation (no bending) |

Vertical |

% |

≥30 |

≥50 |

|

|

Transverse |

≥30 |

≥50 |

||||

|

7 |

breakdown voltage |

No Bending |

Kv |

≥18 |

≥28 |

≥28 |

|

Bending |

≥16 |

≥23 |

≥23 |

|||

|

8 |

Temperature Index (TI) |

℃ |

≥ 155 |

|||

Zhongling insulation material

Related Products

Product inquiry