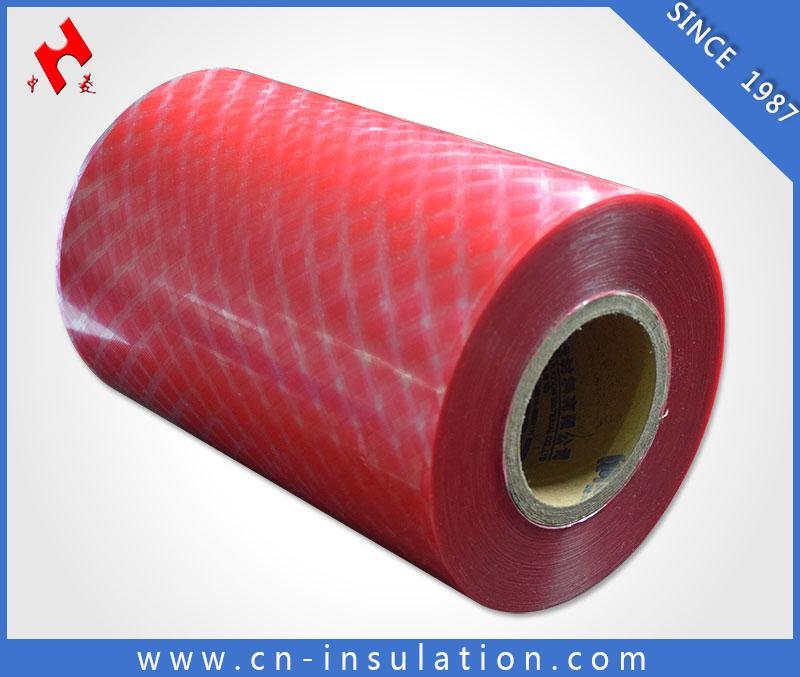

Diamond Dotted Polyester Film

Diamond dotted polyester film with epoxy coating is an insulation material made by coating the electrical polyester film with a special modified epoxy insulating resin in a diamond dotted pattern and then baking it to a semi-cured state. Since the resin coating layer on the diamond dotted polyester film is applied in a dotted pattern rather than as a solid layer, the uncoated channels greatly facilitate the expulsion of air and the infiltration of liquids between insulating materials, thereby minimizing damage from corona discharge and partial discharge. The diamond dotted polyester film can be used as layer insulating materials in the insulation system of air or oil. It is primarily used as layer insulation or turn-to-turn insulation of sulfur hexafluoride mutual inductors and transformers.

Key words:

Oil-Immersed Transformer Insulating Materials | Mutual Inductor Insulation Materials

Classification:

Product Description

Diamond dotted polyester film with epoxy coating is an insulation material made by coating the electrical polyester film with a special modified epoxy insulating resin in a diamond dotted pattern and then baking it to a semi-cured state. Since the resin coating layer on the diamond dotted polyester film is applied in a dotted pattern rather than as a solid layer, the uncoated channels greatly facilitate the expulsion of air and the infiltration of liquids between insulating materials, thereby minimizing damage from corona discharge and partial discharge. The diamond dotted polyester film can be used as layer insulating materials in the insulation system of air or oil. It is primarily used as layer insulation or turn-to-turn insulation of sulfur hexafluoride mutual inductors and transformers.

Product Curing Conditions:

The curing procedure can be done at several temperatures: 90℃ ± 5℃ for 16 hours, or 110℃ ± 5℃ for 6 hours.

Storage:

It shall be stored in a dry, clean, and well-ventilated room with a temperature not exceeding 25℃, and must be kept away from sources of high temperature and direct sunlight. The shelf life is six months. If the material exceeds its shelf life, it can still be used once it passes the test for bond strength and meets the requirements.

Product Curing Conditions:

The curing procedure can be done at several temperatures: 90℃ ± 5℃ for 16 hours, or 110℃ ± 5℃ for 6 hours.

Storage:

It shall be stored in a dry, clean, and well-ventilated room with a temperature not exceeding 25℃, and must be kept away from sources of high temperature and direct sunlight. The shelf life is six months. If the material exceeds its shelf life, it can still be used once it passes the test for bond strength and meets the requirements.

|

Serial Number |

Project |

Unit |

Requirements |

|||

|

DPRCF-05 |

DPRCF-07 |

DPRCF-10 |

||||

|

1 |

substrate thickness |

mm |

0.05±0.005 |

0.07±0.010 |

0.10±0.010 |

|

|

2 |

tensile strength |

Mpa |

≥150 |

|||

|

3 |

Single-side coating thickness |

Μm |

15~20 |

|||

|

4 |

Weight per unit area |

single side coating |

g/cm2 |

76±2 |

102±2 |

144±2 |

|

double-sided coating |

82±3 |

108±3 |

150±3 |

|||

|

5 |

Thermal shrinkage rate |

% |

≤ 3 |

|||

|

6 |

power frequency breakdown voltage |

V |

≥ 6000 |

≥ 7500 |

≥ 9000 |

|

|

7 |

bond strength |

Kpa |

≥35 |

|||

Zhongling insulation material

Related Products

Product inquiry